Recently, I have come across a lot of cases where pellet stoves shut down prematurely after 3 to 6 hours or right after the start cycle when the fire lights up.

Most of these intermittent problems are due to aging parts in the automatic exhaust blower vacuum sensing safety shutdown.

This safety system employs a hose and a vacuum switch. The vacuum hose is connected from the exhaust plenum to the negative port on the vacuum switch. Most pellet stoves use the negative port because the hose barb on the exhaust plenum is sucking air in and pulling the vacuum switch closed. The positive port is where air blows into the vacuum switch and this positive pressure closes the switch. Therefore, if the exhaust blower shuts down or dies the wires connected to the switch cause an open circuit and stop the auger from turning which in turn shuts the stove down. In the case of Englander stoves with dual augers, the switch is only connected to the top auger which also stops the pellets from feeding and shuts the stove down. Usually, this system indicates a bad combustion (exhaust blower) or venting plugged with ash or a dirty stove. It also can indicate a bad door gasket or a bad ash pan gasket if there is one on the stove. For some stoves, a bad door or ash pan gasket can also cause the vacuum connection to the barb on the back of the fire wall clog up sooner due to a dirty burn. A vacuum error can occur if an upgraded high speed blower is installed in a Magnum BabyCountryside stove. To resolve this issue, the damper needs to be adjusted in the air intake on back of the stove. I have also seen the vacuum switch with the hose on the wrong port or the wires not connected to the correct connectors. However, this would cause immediate failure. Always check the above conditions before replacing parts

What can go wrong with an older stove and why?

Aging vacuum hoses get stiff, brittle and crack, and some get stretched where they connect to the hose barb. The bladder type membrane in the vacuum switch also gets weak and may develop a small tear or leak.

Pinpointing these failures can be challenging because the above issues may not show up until the stove heats up. The hose and bladder membrane are connected to either metal or plastic. The heat expansion differs for those two materials which causes a leak and the part fails. Therefore, the auger stops feeding pellets and the stove shuts down.

Some stove manufacturers may have changed the formulations of their switches and hoses to save money. I have seen more failures these days due to such cost saving engineering. In earlier stoves, metal vacuum switches with solid contacts switched the 120 vac going to the auger. Newer stove designs use lighter contacts on plastic vacuum switches that go to the digital control panel and only have to carry a small current or voltage.

Testing the vacuum switch

The wires can be pulled off the vacuum switch and connected together. Make sure that the stove power is disconnected and neither of the vacuum switch connectors touch the chassis or ground. Insert the jumper carefully and plug the power back in.

If you do not feel comfortable doing this, a trained serviceman can do it for you.

Then run the stove to see if it works. If the stove works there is a vacuum detection issue. If the vacuum hose and ports are clean then it is most likely the vacuum switch.

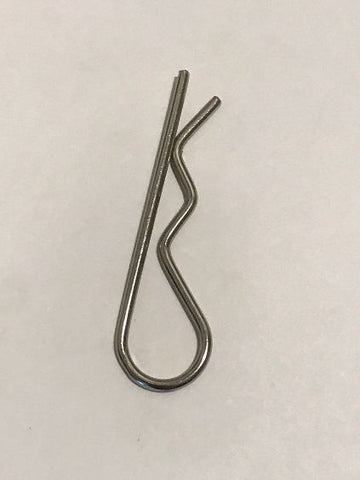

Pic 1 - Shows 18 gauge wire with yellow arrows pointing to 2 male quick disconnect clips that can be purchased at your local hardware store.

Pic 2 - Shows red arrows pointing to vacuum switch terminals where the stove wires were removed. The yellow arrows point to the jumper inserted into the stove connectors for temporary testing.

It is possible if these parts work when the stove is just starting or cooler and test good with a continuity tester or digital mult-meter. These parts can fail when the stove heats up if they are worn or the control panel can be bad and should be replaced. However, a bad control panel will also cause an immediate failure.

What is the best solution to intermittent failure caused by bad vacuum system parts?

At East Coast Hearth, we offer heavy duty metal vacuum switches and high performance, very high temperature natural clear wall silicone vacuum hoses. These are not OEM parts but premium parts from the company that manufacturs them!

Our heavy duty metal vacuum switch may be ordered here. Also see this page for specifications.

Thick Wall High Temperature Hi Performance Vacuum HoseWe sell clear hoses that you can see through to easily notice if there is any ash clogging the hose that can cause your stove to quit.

Most vacuum hoses are 7/32" or 5.9 mm in diameter. We sell 5.9 mm high temperature silicone hoses that fit tightly even with no clamps.

Our clearer hose is stronger, better quality and easier to see soot clogging.

This quality hose has a heavier wall and handles very high temperature and does not crack, or yellow easily.

To understand your problem and the length of hose you need:

Here are examples of vacuum hoses and their lengths with the error status you may see.

Englander 25-PDVC (When there is a bad vacuum switch and/or bad hose, the control panel may or my not show an E1 error)

Original frosty color thick wall vacuum hose is 12.5 inch length from exhaust plenum to vacuum switch 1

Original frosty color thick wall vacuum hose is 9 inch length from fire wall to vacuum switch 2

Enviro Empress (When there is a bad vacuum switch and/or bad hose, the control panel heat level 2 light blinks as stove shuts down)

Original thin wall burnt orange color vacuum hose is 12.5 inch length from exhaust plenum to vacuum switch

Breckwell p-4000 (When there is a bad vacuum switch and/or bad hose, the control panel heat level 2 light blinks as stove shuts down)

Original medium wall red color vacuum hose is 12.5 inch length from back of fire box to vacuum switch

Magnum Baby CountrySide (When there is a bad vacuum switch and/or bad hose, the control panel heat level 2 light blinks as stove shuts down)

Original thin wall red color vacuum hose is 6.5 inch length from back of fire box to vacuum switch

Magnum Baby CountrySide Insert(When there is a bad vacuum switch and/or bad hose, the control panel heat level 2 light blinks as stove shuts down)

Original thin wall clear color vacuum hose is 20 inch length from back of fire box to vacuum switch

1st Pic - Shows new clearer high temperature hose

2nd Pic - Shows Englander vacuum hose that has yellowed and cracked causing the stove to go out after 3 hours

3rd pic - Shows red vacuum hose from a Breckwell P4000 where the ends have stretched out and an orange vacuum hose from a Magnum BabyCountryside that is stiff from age and causes the stove to die out from time to time.

Click on pic to enlarge:

Wood pellet stove vacuum switch history:

The early pellet stoves employed heavy metal vacuum switches with side mounted switches. See picture of an early 1990's Avalon Avanti Vacuum switch and vacuum hose below. These metal vacuum switches were in series with the auger motor and had to carry the same current. New stoves today have plastic switches wired to a digital control panel that only carry a small current. The higher auger motor current is switched by a triac on these electronic control panels. At East Coast Hearth we still sell the heavy metal vacuum switches because they still last longer and work better. Unfortunately the vacuum hose employed in pellet stoves still vary greatly today. They range from the more rubbery and flexible silicone to a harder plastic formulation. The harder plastic can withstand higher temps but are very stiff and not always tight fitting. Some of the more flexible silicone like the one in the picture below is tight fitting but thin wall and can yellow and crack easier. See pic below. At East Coast Hearth we sell only the High Performance Thick wall high temperature flexible silicone hose for not only a tight fit but longer lasting too.

Pic 1 - Shows Englander plastic vacuum switch, Enviro hybrid metal & plastic vacuum switch made by Honeywell and Magnum plastic vacuum switch

Pic 2 - Shows older heavier metal vacuum switch - These metal switches last many years.

Pic 3 - Yellow arrow shows constriction in hose where it was routed under a hold down clamp in back of stove. (Thin wall hose pinches, yellows and cracks)