Click here for additional info on pellet stove control panel failures,

When the control panel fuse blows, finding the cause may be very difficult so here are some steps to help pinpoint the problem

1. Put in a new fuse on the control board/panel and time how many minutes or even seconds it takes from pressing the On button to when the fuse blows.This can help pinpoint which part may be causing the fuse to blow. If the fuse blows after just a few seconds, it may be a part that activates right at start up.When I performed this check for:

Customer1 - The fuse blew 7 seconds after pressing the On button, which indicated it may be the auger motor since it does not get power right away

Customer2 - The fuse blew immediately. This could be the exhaust blower or igniter causing the fuse to blow.However for a room blower it might take 15-20 minutes to blow the fuse. If you are still not sure which part is causing the fuse to blow, the four most common parts to cause this issue are the igniter, auger motor, exhaust blower, and convection blower.

2. Use an AC test cord and multi-meter to test how much current each of those parts draws. Start with the igniter as it is the most common part to cause this issue. Test the part in each step until you get a reading that is too high.

Click here to see the AC Test Cord

3.Take a good multi-meter and put the clamp around one of the igniter wires and plug it into the wall outlet with an AC test cord. It should read 2-3 amps. The multi-meter read 2.1 amps for customer1. See Pic 1 below. That was not too high (over the control panel fuse which is 5 amps in my case) so I continued testing other parts for customer1

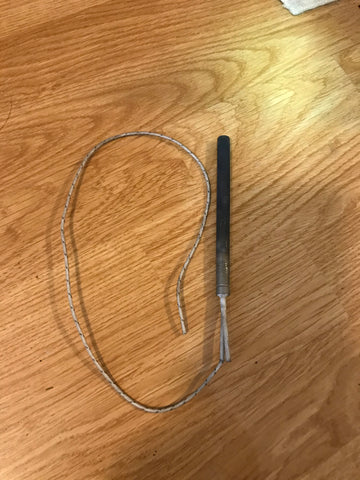

For customer2 even though the igniter read 47 ohms with the ohm meter when plugged directly into the wall AC outlet, the igniter smoked up and one of the wires fell off! Replacing this igniter and the control board fuse fixed the issue and the stove worked fine. See pic 4 of bad igniter.

4. Using the multi-meter, plug the exhaust blower into the wall outlet with the clamp around 1 wire. At start up, it should read about 0.5 amps more than rated for on the motor tag. For my customer it read 1.5 amps for a 1.0 amp motor and then it settled down to 1.0 amp which is stamped on the Fasco motor tag. That was not too high so I continued testing other parts.

5. Using the multi-meter, plug the auger motor into the wall outlet with the clamp around 1 wire. It should read about what is stamped on the motor tag, which was 0.72 amps for my customer's auger motor. However when tested customer2 igniter, it read a whopping 10 amps and within seconds the windings caught on fire. This is very unusual. At 7 seconds when the fuse blew is when the auger started up! I replaced the auger motor and the stove was fixed! See pic 3 below.

6. If the control panel fuse does not blow for about 15 to 20 mins after the On button is pressed then there's a good chance the convection blower caused the fuse to blow. Using the multi-meter, plug the convection or distribution blower into the wall outlet with the clamp around 1 wire. It should read about 0.5 amps more at start up in my case 1.5 amps for a 1.0 amp motor and then settle down to 1.0 amps which is stamped on the motor tag.

Note: If you do not have a multi-meter and you have a few control panel fuses, usually 5 or 6 amps. Disconnect the igniter and then one motor at a time to see if the control panel fuse blows. It it does not blow then the one you just disconnected is bad and should be replaced.

7. If none of the motors draw excessive current then damage to the control board and blown fuses could be caused by power surges from the AC line at the wall outlet. Some examples are electrical storms, electric wires pulled off the house, power surges from generators activated with all breakers on, low quality noisy or dirty power or power fluctuations or brownouts, or unstable electric lines if the house is the last house on the street. This could slowly damage the control panel over 1-3 years! A good surge protector such as Tripp Lite to protect against voltage spikes or even better a Tripp Lite line conditioner for spikes and low voltage conditions can be a life saver for sensitive control panels.Surge Protector

Tripp Lite UltraBlok Surge Protector

Line Conditioner

Tripp Lite Line Conditioner

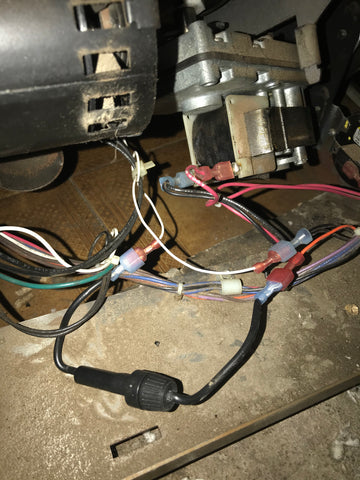

8. The wiring harness in the pellet stove has also known to cause the control panel fuse to blow if the insulation is cut and the bare wire is exposed and touching the metal body of the stove. In one documented case, the control panel was mounted on the side door that swings open and a bundle of wires hit the bottom metal stove edge because the holding clamp adhesive failed. A wire shorted out due to the pressure from the door closing. When the wire ties holding the bundle of wires together were cut, a simple inspection showed a cut in the insulation exposing bare wire. The owner did notice a spark when the side door was closed. In another case the high temperature ceramic wire nut fell off the igniter wire under the firepot and the exposed connection touched the body of the stove causing a short. See pic 5

When I followed the above procedure for my customers, I found the cause for customer1 at step 5 and customer2 at step 3. The solution was simply to replace the auger motor or igniter. If the parts in steps 1-5 draw too high a current, simply replace the part. If you get past step 5, an electrical short in the wiring harness or a surge in the electrical supply may have caused the control board fuse to blow.

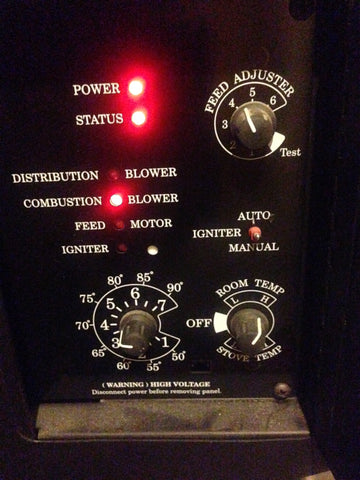

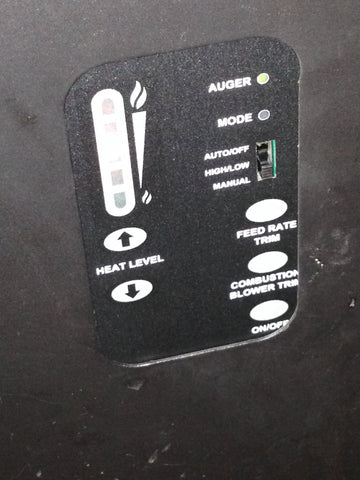

Also when I ran the procedure for both my customers above, the current that blew the control panel fuse did not blow the control panel. This may not always be the case, so if the stove does not work after replacing a bad motor or igniter and the blown fuse, then the control panel may also have to be replaced. See pic 2 below.

The igniter in these stoves draw the most current. Therefore it is highly recommended that if your stove does not have a separate fuse on the igniter, that an inline fuse holder with a Fast Blow Glass Fuse can be easily installed with a male and female quick disconnect clip crimped onto each end. Then it can be plugged into one of the igniter wires in the back of the stove. The correct amperage AGC fuse using E=IR can be easily calculated. For most 300 watt igniters, a 3 amp draw is calculated and another amp is added so any small fluctuation will not blow the fuse. Therefore a 4 amp fuse is sufficient. This will improve the safety of the control board so an igniter that shorts out will not blow the control board fuse and damage the control panel.

Note: These types of shorts can also trip and damage a GFCI outlet or breaker if the stove is plugged into one. After fixing the stove the GFCI may also need replacment.

Pic 1 - Measuring the Igniter current draw

Pic 2 - Adding a 4 Amp Inline AGC type Fast Blow Fuse on your pellet stove Igniter to protect your Control Panel and Control Panel fuse

Pic 3 - Auger motor with burned out windings when tested!

Pic 4 - Igniter drawing excessive current and burned one wire off when tested!

Pic 5 - High temperature ceramic wire nut fell off of igniter wire connection and exposed wire shorted against the stove body under the firepot.