Procedure to Diagnose Issue When your Pellet Stove Control Panel Fuse Blows

Below is additional info for different pellet stove control panel brands

The control panel also known as the Circuit Board, Mother Board, LED panel, touch screen and Control Board can be very difficult to troubleshoot. In this article we will use the term control panel for simplicity. We will go over how they fail and what bug fixes and enhancements they have now for better stove performance! Also why you may want to upgrade!

Maybe the easiest way, is to take the control panel in question and put it in an identical known working stove and see if it works. This may be the best way but is certainly not possible in most circumstances. Therefore, I always check every other component in the stove and if they are all good, then the control panel may be bad. The next step to to analyze the environment and stove install for the second clue. Is the stove in a rural environment where power outages and power fluctuations known as brown outs more common? Does the home or building have whole house surge protection such as an Intermatic Whole House Surge protector or 2 surge protectors in the shape of circuit breakers installed in the circuit panel where the pellet stove outlet is plugged into? In the stove install, is there a good quality surge protector plugged into the AC wall outlet such as a Monster brand or Tripp Lite brand? We do not recommend the very inexpensive surge protectors that can be purchased at the big box stores or the local hardware stores. Also if a generator is used, it must be a pure sinewave generator such as a Honda so damage does not occur to the control panel. If there was no surge protection then a bad control panel is now more possible because the Triacs that switch the AC power are sensative to surges and can be damaged from them.

The last part of the control panel analysis process is knowing the known failures that these boards have and if any of these failures match up. Here is what I have found from my experience.

Components that do not turn on that have no safety switches connected to them point to a damaged control panel. So here are some examples that also help. The assumption here is all components were tested with a test cord to assure they are working and are connected properly and the connectors make a good connection. Many brands updated their control panels to be universal so they can be programmed for each mode. Also some panels have new features and bug fixes.

Just recently I have Replaced some bad Englander Control Panels. One board would not turn the exhaust blower on when the On button was pressed. Measuring the AC voltage at the connectors that were removed from the combustion blower showed 120 VAC but there was not enough current to start the blower going. In this case the AC outlet was tested with an electrical circuit tester and found to have a phase reversal! The neutral wire and hot were reversed on the back of the outlet! After fixing the phase reversal in the AC wall outlet, a new Control Panel fixed the problem and of course a surge protector was added! If the igniter does not light the pellets, it can be a bad control panel. Assure the pellets are dry and the igniter works.

Another case is when the Englander stove warmed up, in this case exactly 50 mins after the on button was pressed, All components ceased to function at the same time! In this case even though the heat sensor was good there board shut down the stove due to a false overheat trigger! In this case a new room blower was installed but you must assure the room blower is working properly and not clogged with dust.

Another example is the Pelpro Accutron II, III or IV Digital panels. They are not only sensitive to surges but if left plugged in when the side panels are removed, they can easily be shorted out and sparks can be seen! I witnessed this first hand and found that when the right side panel where the control panel is located was removed, the metal damper rod fell against the control panel, a big spark was seen and poof the control panel was no good! I have also seen burned components on the back of the board which also indicates a bad control panel. When these panels do not work, they may not light up, or fire the igniter or have other issues.

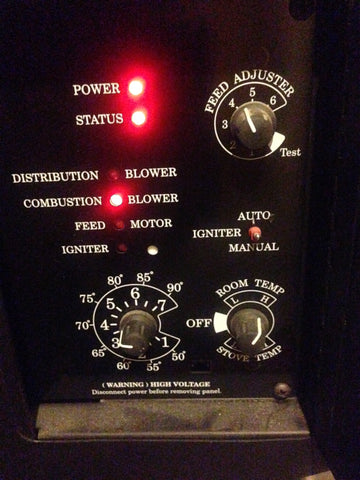

The Harman pellet stoves now have one control panel called a circuit board that fits all their models except the new touch screen. Even though they are sensitive to surges, if they live a long life the control knobs called potentiometers are known to develop flat spots or dead spots where there is no resistance causing the stove to no work or not work properly. I have also seen the fuse blown and a new fuse fixed the problem. In another case the fuse was blown but it would still not feed pellets after a new fuse was inserted. A new circuit board was the fix for that problem. Although the circuit boards have had many updates and bug fixes over the years if the stove is 5 to 10 years or more old, then I recommend replacing the control panel to get the better heat algorythms and updates.

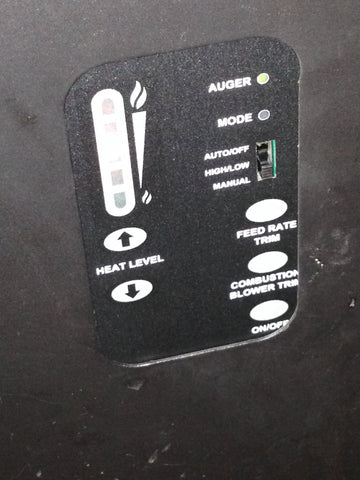

Breckwell pellet stove control panels have been digital for many years. The earlier panels were made to turn the 4 RPM auger motors and 4 RPM augers and motors. After a few years they switched to 1 RPM auger, auger motor with a 1 RPM control panel. In one case I had to replace a panel because the stove was not giving off enough heat. I found that the room blower was not increasing it's speed for each heat level. The new panel fixed the problem. The newest Breckwell panel has the red background behind the Fuel Feed and On buttons, The older panel has a yellow background.

The Enviro control Panel is an example where the board was not only updated to fit most models but also has a new combustion blower trim button. In one case an Enviro Empress control panel was bad and not feeding pellets even though all safety switches were working. Again there was no surge protector on the stove.

The Napoleon was one of the last pellet stoves to get a digital control panel in it's new NPS45 and NPSI45. The latest version has quite a few bug fixes. In one case the pellets were not feeding with a new auger motor and the igniter was not lighting. A new control panel fixed the problem.

A Quadrafire Santa Fe that I picked up was not working at all. I found a burned out fuse in the 3 speed control box. Replacing the 7 amp fuse fix the problem.The new clear control box fixed a start up issue. The issue was not enough vacuum when the stove was below 30 degrees F when the heat level switch was on medium or low. The new clear control box always runs the the exhaust blower on high no matter what the heat level switch is set to during startup to fix the issue. If you have the old solid gray box you may want to upgrade.

In conclusion, there are many signs that point to a bad control panel and when no other part can fix the problem, then the control panel needs to be replaced.